One of main causes of high splice loss is bad cleave end face. The 90S+ analyzes the condition of both L and R cleave end faces and performs optimal fusion control. This new technology improves splice loss significantly and reduces the risk of re-installa

Liên hệ : 08.1800.3023

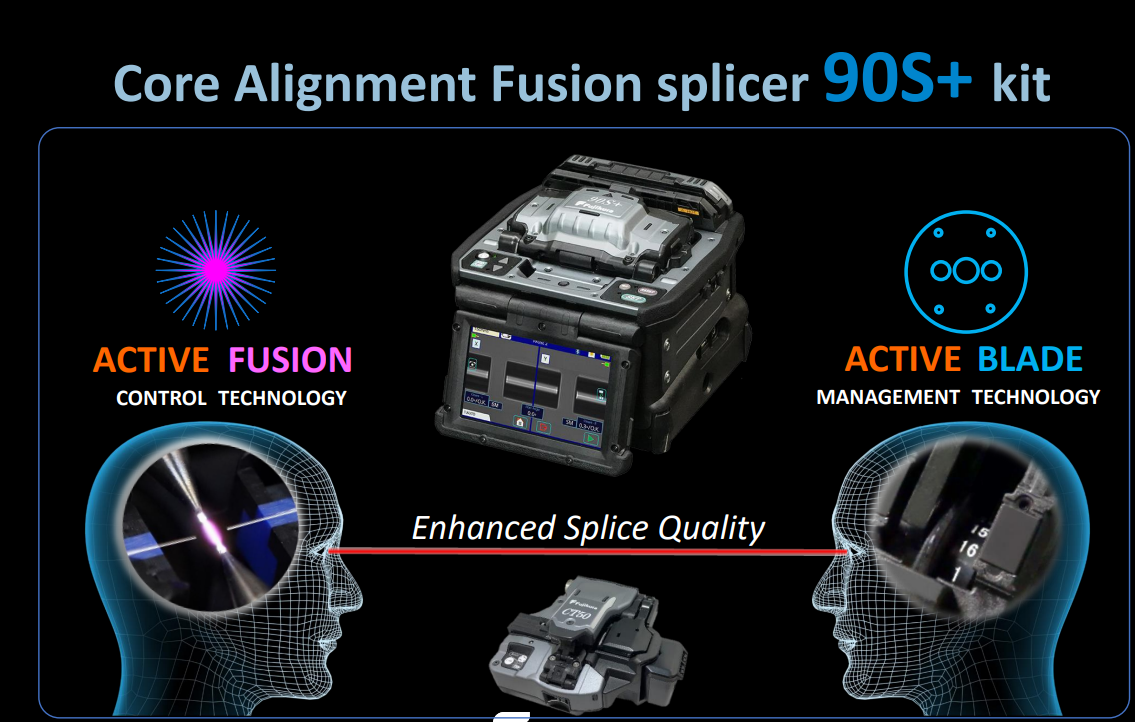

Active Fusion Control Technology

1. Active Fusion control by cleave condition

One of main causes of high splice loss is bad cleave end face. The 90S+ analyzes the condition of both L and R cleave end faces and performs optimal fusion control. This new technology improves splice loss significantly and reduces the risk of re-installation.

[img]

Splice loss with large cleave angle : 3 <θ< 5 degree

[img]

*G.652 splicing result measured with a cut-back method. The splicing result changes depending on the fiber type and fiber characteristics.

2. Active Fusion control by fiber brightness.

Fusion is easily affected by changes in the environment. The 90S+ uses real-time fusion parameter control by analyzing the fiber’s brightness intensity during fusion. It contributes to stable, reduced splice loss.

[img]

3. Active Fusion control by fiber discrimination.

Adequate splice parameters may differ depending on fiber type. The 90S+ automatically applies the optimum splice parameters depending on the fiber type.

[img]

Active Blade Management Technology

1. Active Blade rotation by motor.

The 90S+ and CT50 fiber cleaver are enabled with wireless data connectivity. This capability allows automatic cleaver blade rotation when the 90S+ judges the blade is worn. The 90S+ can connect to two CT50s simultaneously.

[img]

2. Active Blade life management.

The 90S+ displays the remaining blade life and informs the user when a blade height change, position change, or new blade is required.

[img]

Operation Time Reduction

1. Automatic Open-Close Wind protectors.

The faster automated features of the 90S+ reduce installation times. With this splicer, an operator can complete the entire splice process from splicing to heating without touching the 90S+ and only moving the fiber

[img]

2. Operation time reduction.

The shape of the sheath clamp is optimized for 60mm length protection sleeves. The length from splice point to the edge of the sheath clamp is 30mm. Therefore, it is easy to center the protection sleeve over the splice by using your fingers to reference the splice point.

[img]

3. Fiber retention clamp.

The fiber retention clamps support the automated operations. When the sheath clamps open automatically after splicing, the fiber retention clamps gently hold the spliced fiber to keep it from flying out. The retention clamps release when the fiber is lifted by the operator.

[img]

4. Operation time reduction.

These functions enable the 90S+ to reduce operation time by 50% over the previous model.

[img]

User Friendly

1. Carrying Case.

There are multiple ways to utilize the 90S carrying case. The 90S+ is ready to use just by opening the case, but it is also possible to use the 90S+ on top of the carrying case or only with the work tray depending on the work environment.

[img]

2. Work Tray.

The newly designed work tray has many functions. There are two drawers for storage which are large enough to store tools or battery packs. Also, the work tray can be divided in two, so it is configurable to fit your work space.

[img]

3. Loose tube Compatibility.

The sheath clamp of the 90S+ is compatible with loose tube fiber. The Protrusion part on of the sheath clamp for loose tube fiber engages or retracts by simply changing the switch position with your finger.

[img]

4. Tool-less Electrodes and illumination.

The 90S+ electrodes come as an “assy” including the fixing screw. You can rotate the screw by hand without tools, enabling easy electrode replacement.

[img]

The transparent electrode covers support wider illumination of the v-groove. As the sheath clamp opens on the opposite side of the illumination lamp, the sheath clamp area is illuminated without shadow.

[img]

Standard Package

90S+ Standard Package

[table] [img]

Specifications

90S+ Standard Package [table]

90S+ Options [table]

CT50 Specifications [table] [image]

CT50 Options [table] [image]

1. Active Fusion control by cleave condition

One of main causes of high splice loss is bad cleave end face. The 90S+ analyzes the condition of both L and R cleave end faces and performs optimal fusion control. This new technology improves splice loss significantly and reduces the risk of re-installation.

[img]

Splice loss with large cleave angle : 3 <θ< 5 degree

[img]

*G.652 splicing result measured with a cut-back method. The splicing result changes depending on the fiber type and fiber characteristics.

2. Active Fusion control by fiber brightness.

Fusion is easily affected by changes in the environment. The 90S+ uses real-time fusion parameter control by analyzing the fiber’s brightness intensity during fusion. It contributes to stable, reduced splice loss.

[img]

3. Active Fusion control by fiber discrimination.

Adequate splice parameters may differ depending on fiber type. The 90S+ automatically applies the optimum splice parameters depending on the fiber type.

[img]

Active Blade Management Technology

1. Active Blade rotation by motor.

The 90S+ and CT50 fiber cleaver are enabled with wireless data connectivity. This capability allows automatic cleaver blade rotation when the 90S+ judges the blade is worn. The 90S+ can connect to two CT50s simultaneously.

[img]

2. Active Blade life management.

The 90S+ displays the remaining blade life and informs the user when a blade height change, position change, or new blade is required.

[img]

Operation Time Reduction

1. Automatic Open-Close Wind protectors.

The faster automated features of the 90S+ reduce installation times. With this splicer, an operator can complete the entire splice process from splicing to heating without touching the 90S+ and only moving the fiber

[img]

2. Operation time reduction.

The shape of the sheath clamp is optimized for 60mm length protection sleeves. The length from splice point to the edge of the sheath clamp is 30mm. Therefore, it is easy to center the protection sleeve over the splice by using your fingers to reference the splice point.

[img]

3. Fiber retention clamp.

The fiber retention clamps support the automated operations. When the sheath clamps open automatically after splicing, the fiber retention clamps gently hold the spliced fiber to keep it from flying out. The retention clamps release when the fiber is lifted by the operator.

[img]

4. Operation time reduction.

These functions enable the 90S+ to reduce operation time by 50% over the previous model.

[img]

User Friendly

1. Carrying Case.

There are multiple ways to utilize the 90S carrying case. The 90S+ is ready to use just by opening the case, but it is also possible to use the 90S+ on top of the carrying case or only with the work tray depending on the work environment.

[img]

2. Work Tray.

The newly designed work tray has many functions. There are two drawers for storage which are large enough to store tools or battery packs. Also, the work tray can be divided in two, so it is configurable to fit your work space.

[img]

3. Loose tube Compatibility.

The sheath clamp of the 90S+ is compatible with loose tube fiber. The Protrusion part on of the sheath clamp for loose tube fiber engages or retracts by simply changing the switch position with your finger.

[img]

4. Tool-less Electrodes and illumination.

The 90S+ electrodes come as an “assy” including the fixing screw. You can rotate the screw by hand without tools, enabling easy electrode replacement.

[img]

The transparent electrode covers support wider illumination of the v-groove. As the sheath clamp opens on the opposite side of the illumination lamp, the sheath clamp area is illuminated without shadow.

[img]

Standard Package

90S+ Standard Package

[table] [img]

Specifications

90S+ Standard Package [table]

90S+ Options [table]

- Cleave length range depending on fiber type

- 5 to 16mm : 125μm cladding dia. and 250μm coating dia.

- 10 to 16mm : 125μm cladding dia. and 400 or 900μm coating dia.

- 5 to 10mm : 80μm cladding dia. and 160μm coating dia.

- 5 to 16mm : 150μm cladding dia. and 250μm coating dia.

- Measured with a cut-back method relevant to ITU-T and IEC standard after splicing Fujikura identical fibers. The average splice loss changes depending on the environmental condition and fiber characteristics.

- Measured at room temperature. The definition of splice time is from the fiber image appearing on LCD monitor to the estimated loss displayed. The average splice time changes depending on the environmental conditions, fiber type, and fiber characteristics.

- Measured at room temperature with the AC adapter. The heat time is defined from the start beep sound to the finish beep sound. The average heat time changes depending on the environmental conditions, sleeve type and battery pack condition.

- The electrode life changes depending on the environmental conditions, fiber type and splice modes.

- Test condition

- Splice and heat time : 1 minute cycle

- Using the splicer power save settings

- Using a not degraded battery

- At room temperature The battery capacity changes when testing with different conditions from the above.

- The battery capacity decreases to a half after approx. 500 discharge and recharge cycles, The battery life is shortened further when using outside of the storage temperature range, operating temperature range, if completely discharged by storing for a long time without recharging.

- Bluetooth® mark and logos are the registered trademarks of Bluetooth SIG, Inc.

CT50 Specifications [table] [image]

CT50 Options [table] [image]

- When the cleave length is less than 10mm, the coating diameter should be 250µm or less. Also, a blade height adjustment is required before cleaving. The average cleave angle is worse than the specification when the cleave length is less than10mm.

- Measured with an interferometer at room temperature, not with a splicer. A new blade was used to cleave both the single fibers and ribbon fibers. The average cleave angle changes depending on the environmental conditions, blade condition, operating method, and cleanliness.

- The blade life changes depending on the environmental conditions, operating method, and the fiber type cleaved.

- Measured in a condition when closing the lever. *5 Bluetooth® mark and logos are the registered trademarks of Bluetooth SIG, Inc.

Default information